Mastering Concrete Pumping Efficiency with the Concret Pump Piston Ramp

October 18, 2023

Say Goodbye to Vibrations with Anti-Vibration Rubber Feet Stand Mounting!

December 20, 2023Silicone rubber, often referred to simply as “silicone,” is a versatile and unique material with a wide range of applications across various industries. In this comprehensive blog post, we will explore the properties, uses, advantages, and production methods of silicone rubber. By the time you finish reading, you’ll have a profound understanding of the significance of silicone rubber in our modern world.

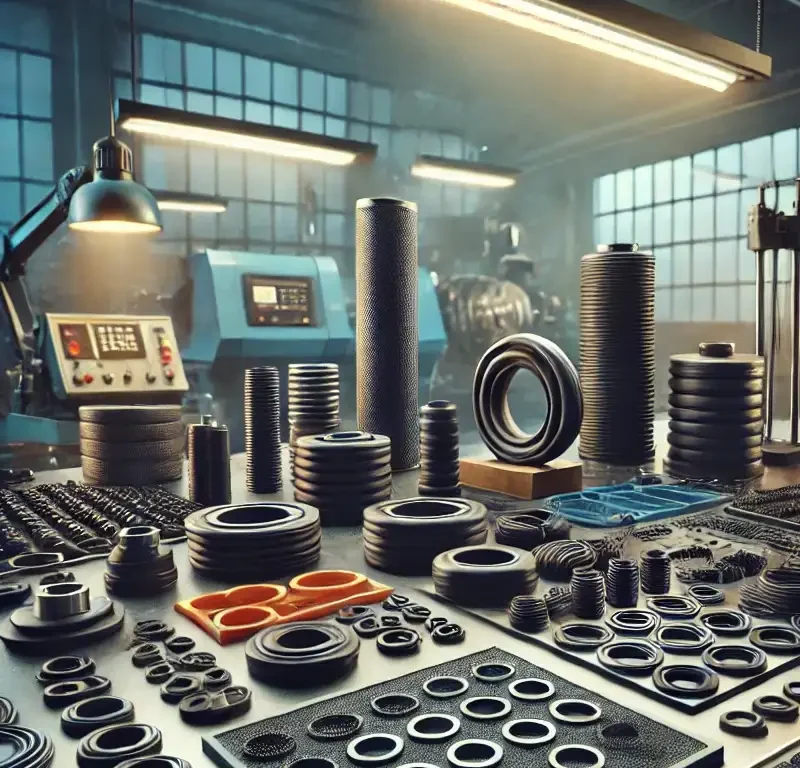

Introduction to Silicone Rubber

Silicone rubber is a synthetic polymer made from silicon, oxygen, carbon, and hydrogen. It is known for its exceptional properties, making it highly suitable for a myriad of applications. These properties include:

- Temperature Resistance: Silicone rubber can withstand extreme temperatures, from as low as -60°C to as high as 250°C, without losing its flexibility or other physical properties. This makes it ideal for both extreme cold and hot environments.

- Durability: Silicone rubber is highly resistant to wear and tear, ensuring its longevity in various applications.

- Flexibility: Its flexibility allows it to maintain its shape and properties even under stress, making it an excellent choice for seals and gaskets.

- Chemical Resistance: Silicone rubber resists damage from chemicals, solvents, and UV radiation, ensuring stability in harsh environments.

- Non-Toxicity: It is non-toxic and biocompatible, making it safe for use in medical and food-related applications.

Now that we’ve covered its properties, let’s explore some of the many ways silicone rubber is utilized.

Applications of Silicone Rubber

Medical Industry: Silicone rubber is commonly used in the medical industry for various applications, such as medical implants, tubing, and seals. Its biocompatibility and non-reactive properties make it a safe choice for medical devices.

Electronics: Silicone rubber’s electrical insulation properties make it suitable for electrical insulators, keypads, and gaskets in electronics.

Aerospace*: It is used in aerospace for its ability to withstand extreme temperatures and maintain sealing and insulation properties.

Construction*: In the construction industry, silicone rubber is used for sealing and insulation, including in doors, windows, and roofing.

Automotive*: Silicone rubber plays a significant role in the automotive sector for gaskets, hoses, seals, and spark plug boots due to its resistance to automotive fluids and temperature extremes.

Cookware and Bakeware*: Silicone rubber is also used in the kitchen as a non-stick coating in cookware and bakeware due to its food-grade safety.

Advantages of Silicone Rubber

- Longevity: Silicone rubber products have a longer lifespan compared to many other materials due to their excellent resistance to wear and tear.

- Easy Maintenance: They are easy to clean and maintain, making them ideal for applications in which hygiene is crucial.

- Versatility: Silicone rubber can be molded into various shapes and sizes, allowing for custom solutions in different industries.

- Temperature Tolerance: The ability to maintain their properties over a wide temperature range is a standout feature, especially for extreme environments.

- Safety: Silicone rubber is non-toxic, making it safe for use in applications involving contact with food, people, or sensitive equipment.

Production of Silicone Rubber

The production of silicone rubber involves several steps, including:

- Hydrolysis: The production begins with hydrolysis, which converts silicon metal into siloxanes, the basic building blocks of silicone rubber.

- Polymerization: Siloxanes are then polymerized to create the silicone polymer, often under the influence of a catalyst.

- Processing: The silicone polymer is processed, which can involve heating, cooling, or curing to achieve the desired physical properties.

- Molding and Shaping: The processed silicone is molded into various forms, depending on the intended application.

Conclusion

Silicone rubber is a remarkable material that has found its way into numerous industries, enhancing product quality, safety, and longevity. Its exceptional properties, versatility, and ease of production have made it a material of choice for applications ranging from medical devices to cookware and everything in between. The continued development of silicone rubber promises even more innovative applications in the future, ensuring that this remarkable material remains indispensable in our modern world.