Heavy duty rubber hoses

December 28, 2020

Butterfly valve sleeves

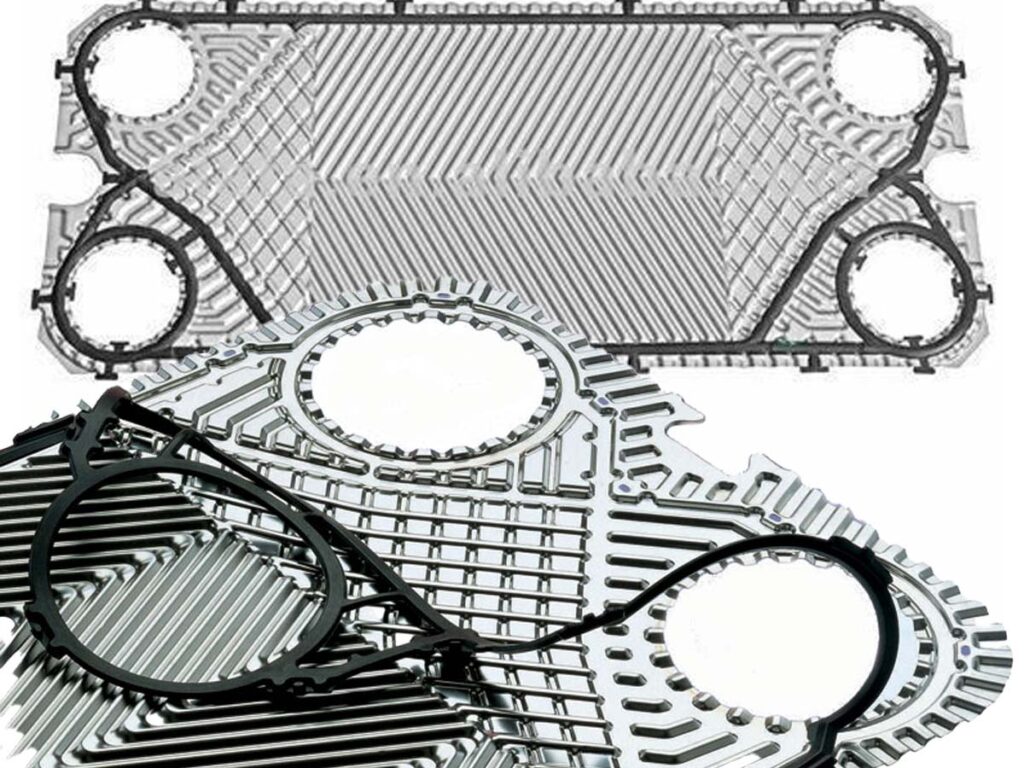

December 29, 2020Heat exchanger gaskets by Ali Enterprises Pakistan

The genuine desire of gasket traits is important to the powerful operation of the Plate Heat Exchanger. Since the bulk of Plate Heat Exchanger gaskets are made from perishable rubber polymers, they require changing because the gasket loses the cap potential to seal thru hardening and deterioration.

Vital Properties

Incompressibility – The rubber compounds behaves as though it has been a liquid which could alternate form however can not waft so that once being squeezed it’s going to go back to its authentic vulcanized form. Strength – It is powerful sufficient to resist the forces usually incurred with the aid of using squeezing into the role and being acted upon with the aid of using pressurized liquid. Softness – This is adjusted with the aid of using compounding in order that the rubber is powerful sufficient for the utility however nonetheless smooth sufficient to comply carefully to the metallic surfaces and offers a seal without undue stresses being applied.

Resistance to Fluid – The excessive molecular weight, the cross-related polymer matrix is proof against penetration with the aid of using any fluid of an assorted chemical nature to itself. Resistance to Temperature – One drawback of the desired ‘rubberiness’ of the polymer fabric is the truth that each one polymer will simplest behave as rubber over a fairly brief variety of temperature. Thus the correct choice of the compound in line with the desired temperature variety is important.

Longevity – Many cutting-edge artificial polymers have an integrated superiority in phrases of a beneficial lifetime over older substances, and cutting-edge components can in addition beautify this property. It is a place that an appropriate compound choice is of crucial importance: all rubber primarily based totally compounds be afflicted by strain relaxation, i.e the preliminary sealing pressure slowly declines in the course of use because of adjustments withinside the inner chemistry of the compound, and while the sealing pressure declines to beneath a price relying at the utility, leaks will ensue.2 Plate Heat Exchanger Gasket MaterialsFor plate (and frame) warmth exchangers, the usual substances are EPDM and Nitrile rubber (NBR). EPDM is used usually for non-fatty/oily packages and NBR for oil/fats packages. However, there aren’t any policies without exceptions. An “oil” and fatty utility might also additionally have a low-fats content, making the utility extra appropriate for EPDM in place of NBR.

Other rubbers used for PHE’s are Hydrogenated Nitrile Rubber (HNBR), Fluorocarbon Rubber (FKM), Butyl, Chloroprene Rubber (GR), Chlorsulphonated Polyethylene (CSM), Styrene-Rubber (SBR), Natural Rubber (NR) and Silicone Rubber (Q) are much less not unusual place ones. All components depend for the product properties, and now no longer simplest have an effect on the first-class degree of the product, however, additionally, they have an impact on the consistency of the first-class degree. LifetimeEventually, all rubber substances will degrade, dropping their properties, making them wrong for in additional use.

It is all a depend of time and the authentic first-class of the product. The life of rubber merchandise is depending on the environment (chemical types, concentrations) and temperature. Also, temperature adjustments and strain adjustments have an effect on the overall performance and lifelong of the rubber product. Chemical ResistanceEach rubber fabric has a completely unique resistance to numerous chemical compounds. The polymer used, in addition to components, impacts which chemical compounds every rubber fabric is appropriate for.

Visit our Fb Page for more information

Vital Properties

Incompressibility – The rubber compounds behaves as though it has been a liquid which could alternate form however can not waft so that once being squeezed it’s going to go back to its authentic vulcanized form. Strength – It is powerful sufficient to resist the forces usually incurred with the aid of using squeezing into the role and being acted upon with the aid of using pressurized liquid. Softness – This is adjusted with the aid of using compounding in order that the rubber is powerful sufficient for the utility however nonetheless smooth sufficient to comply carefully to the metallic surfaces and offers a seal without undue stresses being applied.

Resistance to Fluid – The excessive molecular weight, the cross-related polymer matrix is proof against penetration with the aid of using any fluid of an assorted chemical nature to itself. Resistance to Temperature – One drawback of the desired ‘rubberiness’ of the polymer fabric is the truth that each one polymer will simplest behave as rubber over a fairly brief variety of temperature. Thus the correct choice of the compound in line with the desired temperature variety is important.

Longevity – Many cutting-edge artificial polymers have an integrated superiority in phrases of a beneficial lifetime over older substances, and cutting-edge components can in addition beautify this property. It is a place that an appropriate compound choice is of crucial importance: all rubber primarily based totally compounds be afflicted by strain relaxation, i.e the preliminary sealing pressure slowly declines in the course of use because of adjustments withinside the inner chemistry of the compound, and while the sealing pressure declines to beneath a price relying at the utility, leaks will ensue.2 Plate Heat Exchanger Gasket MaterialsFor plate (and frame) warmth exchangers, the usual substances are EPDM and Nitrile rubber (NBR). EPDM is used usually for non-fatty/oily packages and NBR for oil/fats packages. However, there aren’t any policies without exceptions. An “oil” and fatty utility might also additionally have a low-fats content, making the utility extra appropriate for EPDM in place of NBR.

Other rubbers used for PHE’s are Hydrogenated Nitrile Rubber (HNBR), Fluorocarbon Rubber (FKM), Butyl, Chloroprene Rubber (GR), Chlorsulphonated Polyethylene (CSM), Styrene-Rubber (SBR), Natural Rubber (NR) and Silicone Rubber (Q) are much less not unusual place ones. All components depend for the product properties, and now no longer simplest have an effect on the first-class degree of the product, however, additionally, they have an impact on the consistency of the first-class degree. LifetimeEventually, all rubber substances will degrade, dropping their properties, making them wrong for in additional use.

It is all a depend of time and the authentic first-class of the product. The life of rubber merchandise is depending on the environment (chemical types, concentrations) and temperature. Also, temperature adjustments and strain adjustments have an effect on the overall performance and lifelong of the rubber product. Chemical ResistanceEach rubber fabric has a completely unique resistance to numerous chemical compounds. The polymer used, in addition to components, impacts which chemical compounds every rubber fabric is appropriate for.

Visit our Fb Page for more information