Rubber Flooring: Enhancing Safety and Performance in High-Traffic Areas

February 1, 2025

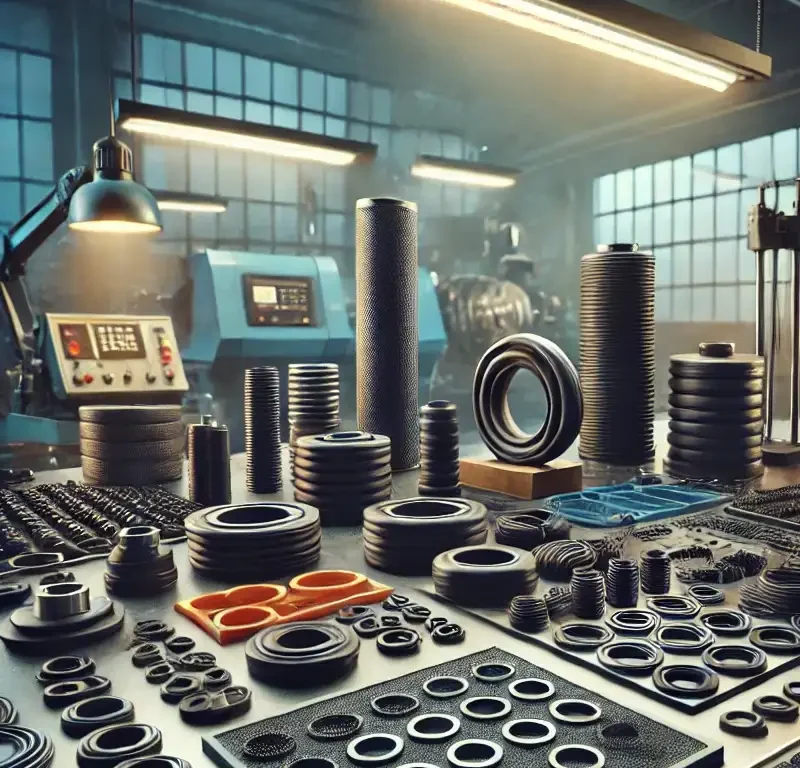

Unlock the Power of Precision Rubber Manufacturing with Ali Enterprises

February 15, 2025Introduction In industrial operations, the quality of components plays a critical role in ensuring safety, longevity, and overall efficiency. Industrial rubber parts are no exception. Investing in high-grade rubber components is not just a matter of preference but a necessity for maintaining reliable and cost-effective operations.

The Risks of Low-Quality Rubber Parts

1. Frequent Failures and Downtime Low-quality rubber parts are prone to wear and tear, leading to frequent failures. This not only disrupts operations but also increases downtime, which can be costly for businesses relying on continuous production.

2. Safety Hazards Compromised rubber parts can lead to safety hazards, especially in high-pressure or high-temperature environments. For example, a substandard rubber seal might fail to prevent leaks in a hydraulic system, posing a risk to both equipment and personnel.

3. Increased Maintenance Costs While low-cost rubber parts might seem like a good deal initially, the frequent need for replacements and repairs quickly adds up. High-quality parts, on the other hand, offer longer service life, reducing the overall maintenance costs.

The Benefits of High-Grade Industrial Rubber Parts

1. Enhanced Durability High-grade rubber parts are designed to withstand harsh industrial conditions, including extreme temperatures, chemical exposure, and mechanical stress. This durability translates to fewer replacements and longer intervals between maintenance cycles.

2. Improved Performance Superior materials and manufacturing processes ensure that high-quality rubber parts perform consistently, maintaining the integrity of seals, reducing vibrations, and ensuring smooth operations.

3. Cost-Effectiveness Although high-grade rubber parts may come with a higher upfront cost, their long-term value is undeniable. By reducing downtime, maintenance, and the risk of costly failures, these parts provide a better return on investment.

Case Study: The Long-Term Savings of Quality Rubber Parts

A manufacturing company switched to high-grade rubber seals and gaskets after experiencing frequent breakdowns with cheaper alternatives. The result was a 40% reduction in maintenance costs over a year, along with improved safety and operational efficiency.

Key Considerations When Choosing Rubber Parts

1. Material Compatibility Ensure the rubber material is compatible with the environment it will be used in, such as exposure to chemicals, extreme temperatures, or mechanical stress.

2. Supplier Reputation Choose a reputable supplier, like Ali Enterprises, known for producing high-quality industrial rubber parts. A reliable supplier can offer both standard and customized solutions that meet your specific needs.

3. Industry Standards Ensure the rubber parts comply with industry standards and certifications, which is a testament to their quality and reliability.

Conclusion

Investing in high-grade industrial rubber parts is essential for any business aiming to maintain safe, efficient, and cost-effective operations. By prioritizing quality, you not only safeguard your machinery and personnel but also enhance the overall performance and profitability of your operations.

FAQs

1. What are the signs of low-quality rubber parts? Frequent cracking, hardening, and failure under stress are common signs of low-quality rubber parts.

2. How do high-grade rubber parts reduce costs? They reduce costs by lowering the frequency of replacements, minimizing downtime, and enhancing the overall efficiency of operations.

3. Can investing in quality rubber parts improve safety? Yes, high-quality rubber parts are more reliable, reducing the risk of failures that could lead to safety hazards.

4. What should I look for in a supplier of rubber parts? Look for a supplier with a strong reputation, certifications, and the ability to provide customized solutions.

5. Are there industry standards for rubber parts? Yes, ensuring that your rubber parts meet industry standards is crucial for guaranteeing their quality and reliability.