How Rubber Manufacturers Are Innovating in Sustainable Flooring Solutions

December 1, 2024

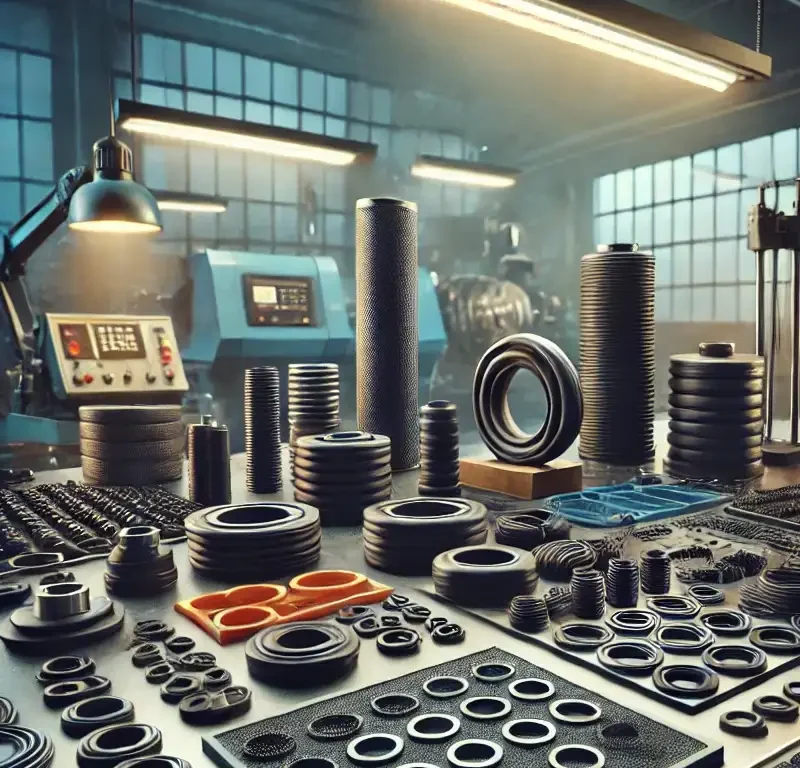

The Ultimate Guide to Rubber Parts: What Ali Enterprises Has to Offer!

December 15, 2024Introduction Selecting the right industrial rubber parts is crucial for the efficiency and longevity of your machinery and operations. With a myriad of options available, understanding the key factors to consider can help you make informed decisions that align with your business needs.

Understanding Industrial Rubber Parts

1. Material Selection The choice of material is paramount when selecting rubber parts. Common materials include:

- Natural Rubber: Ideal for shock absorption and flexibility.

- EPDM: Known for its excellent resistance to heat, ozone, and weathering.

- Nitrile (NBR): Best for oil and fuel resistance.

- Silicone: Suitable for extreme temperatures and chemical exposure.

Each material has unique properties, making it suitable for specific applications. Consider the environment in which the parts will operate to determine the most appropriate material.

2. Durability and Longevity The durability of industrial rubber parts directly impacts maintenance costs and operational downtime. High-quality rubber parts not only last longer but also perform better under stress. Evaluate the part’s ability to withstand:

- Abrasive conditions

- Chemical exposure

- Temperature fluctuations

Durability often correlates with the material grade and the manufacturing process, so prioritize suppliers known for their stringent quality standards.

3. Application-Specific Needs Different applications require different types of rubber parts. For example:

- Seals and Gaskets: Essential for preventing leaks in pipelines and machinery.

- Anti-Vibration Mounts: Crucial for reducing vibrations in heavy machinery, enhancing performance, and extending the equipment’s lifespan.

- O-Rings: Commonly used in static or dynamic sealing applications.

Understanding the specific demands of your application will help you choose the right part, ensuring optimal performance and safety.

4. Customization and Supplier Reliability In many cases, off-the-shelf rubber parts may not meet your precise requirements. Working with a supplier who offers customization can be a game-changer. They can tailor the size, shape, and material composition to fit your exact specifications.

Additionally, consider the supplier’s reliability:

- Consistent Quality: Ensure the supplier maintains high standards across all products.

- Timely Delivery: Avoid production delays by partnering with a supplier known for punctual deliveries.

- Technical Support: Choose a supplier that provides ongoing support and can help you troubleshoot issues.

5. Cost vs. Value While it might be tempting to opt for cheaper options, consider the long-term value of investing in high-quality rubber parts. Though the upfront cost may be higher, these parts typically offer better durability, reducing the need for frequent replacements and minimizing downtime.

Conclusion Choosing the right industrial rubber parts involves careful consideration of material selection, durability, application-specific requirements, and supplier reliability. By prioritizing quality and suitability for your specific needs, you can enhance the efficiency and longevity of your operations, ultimately saving costs in the long run.

FAQs

1. What is the most durable type of rubber for industrial parts? Nitrile (NBR) and EPDM are among the most durable, with NBR excelling in oil resistance and EPDM in heat and weather resistance.

2. How can I ensure my rubber parts last longer? Select high-quality materials, ensure proper installation, and maintain the parts regularly to maximize their lifespan.

3. Can industrial rubber parts be customized? Yes, many suppliers offer customization to meet specific application requirements, including size, shape, and material composition.

4. What are the most common applications of industrial rubber parts? Common applications include seals and gaskets, anti-vibration mounts, and O-rings for sealing mechanisms.

5. How do I choose a reliable supplier for rubber parts? Look for suppliers with a strong track record of quality, timely delivery, and excellent customer support.