Eid Greeting 2022

April 29, 2022

What is Food Grade Conveyor Belt

March 14, 2023Silicone Rubber Rollers

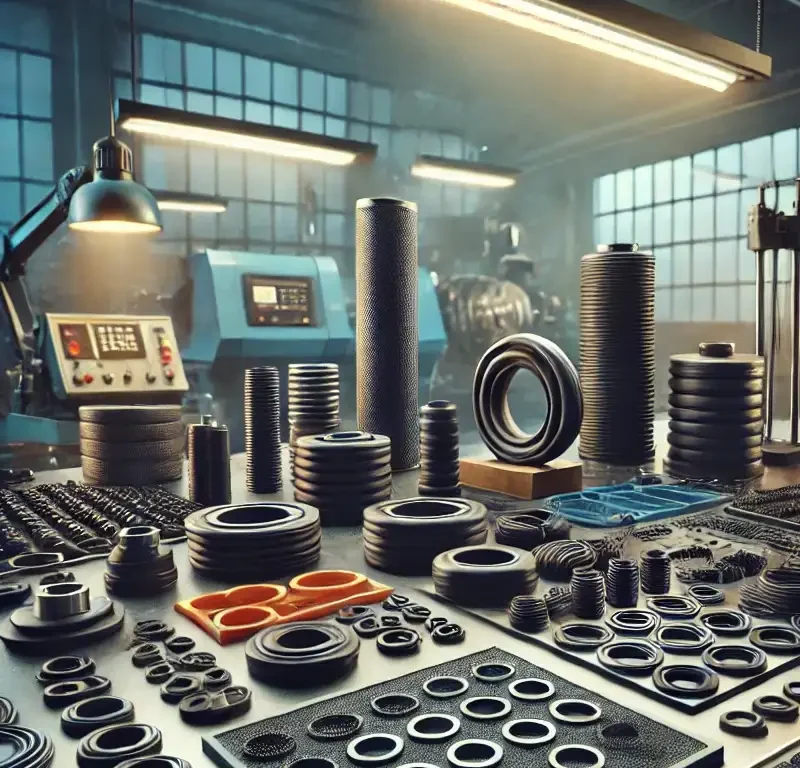

Silicone rubber rollers are widely used in various industrial applications due to their unique properties and advantages over other types of rollers. These rollers are made of silicone rubber, a synthetic material that is known for its excellent thermal and chemical resistance, durability, and flexibility. In this article, we will discuss the applications, benefits, and manufacturing process of silicone rubber rollers.

Applications of Silicone Rubber Rollers

Silicone rubber rollers are used in a wide range of applications, including printing, laminating, embossing, coating, and converting. Here are some of the most common applications of silicone rubber rollers:

-

Printing: Silicone rubber rollers are commonly used in printing presses to transfer ink from the printing plate onto the substrate. They offer excellent ink transfer properties, smoothness, and durability, resulting in high-quality prints.

-

Laminating: Silicone rubber rollers are used in laminating machines to bond two or more materials together. They provide excellent adhesive properties, high temperature resistance, and dimensional stability, resulting in a strong and durable bond.

-

Embossing: Silicone rubber rollers are used in embossing machines to create raised or recessed patterns on various materials such as paper, plastic, and metal. They provide excellent surface conformity and dimensional stability, resulting in precise and consistent embossed patterns.

-

Coating: Silicone rubber rollers are used in coating machines to apply a thin layer of liquid or powder coating onto various substrates. They provide excellent coating properties, smoothness, and durability, resulting in a high-quality finish.

-

Converting: Silicone rubber rollers are used in converting machines to convert raw materials into finished products such as labels, tapes, and films. They provide excellent feeding and pulling properties, non-slip surface, and durability, resulting in a smooth and efficient converting process.

Manufacturing Process of Silicone Rubber Rollers

The manufacturing process of silicone rubber rollers involves several steps, including material selection, compounding, molding, and finishing. Here are the steps involved in the manufacturing process of silicone rubber rollers:

-

Material selection: The first step in the manufacturing process is to select the appropriate silicone rubber compound based on the desired properties and application requirements.

-

Compounding: The selected silicone rubber compound is mixed with various additives such as fillers, pigments, and curing agents to achieve the desired properties and characteristics.

-

Molding: The compounded silicone rubber is then molded into the desired shape and size using various molding techniques such as compression molding, transfer molding, or injection molding.

-

Finishing: The molded silicone rubber rollers are then subjected to various finishing processes such as grinding, polishing, or coating to achieve the desired surface finish and dimensional accuracy.

Benefits of Silicone Rubber Rollers

Silicone rubber rollers offer several benefits over other types of rollers, making them a popular choice in various industrial applications. Here are some of the benefits of silicone rubber rollers:

-

Thermal resistance: Silicone rubber rollers can withstand high temperatures up to 500°F (260°C), making them suitable for applications that involve high heat exposure.

-

Chemical resistance: Silicone rubber rollers are resistant to a wide range of chemicals, including acids, alkalis, and solvents, making them suitable for applications that involve exposure to harsh chemicals.

-

Durability: Silicone rubber rollers are highly durable and can withstand repeated use without degradation or loss of performance.

-

Flexibility: Silicone rubber rollers are highly flexible and can conform to uneven surfaces, resulting in smooth and efficient operation.

-

Non-stick properties: Silicone rubber rollers have excellent non-stick properties, preventing adhesives or inks from sticking to the roller surface, resulting in a cleaner and more efficient operation.

Conclusion

Silicone rubber rollers are a versatile and reliable solution for various industrial applications that require high-temperature resistance, chemical resistance, durability, and