Ali Enterprises: The Best-Kept Secret in Industrial Rubber

February 25, 2025

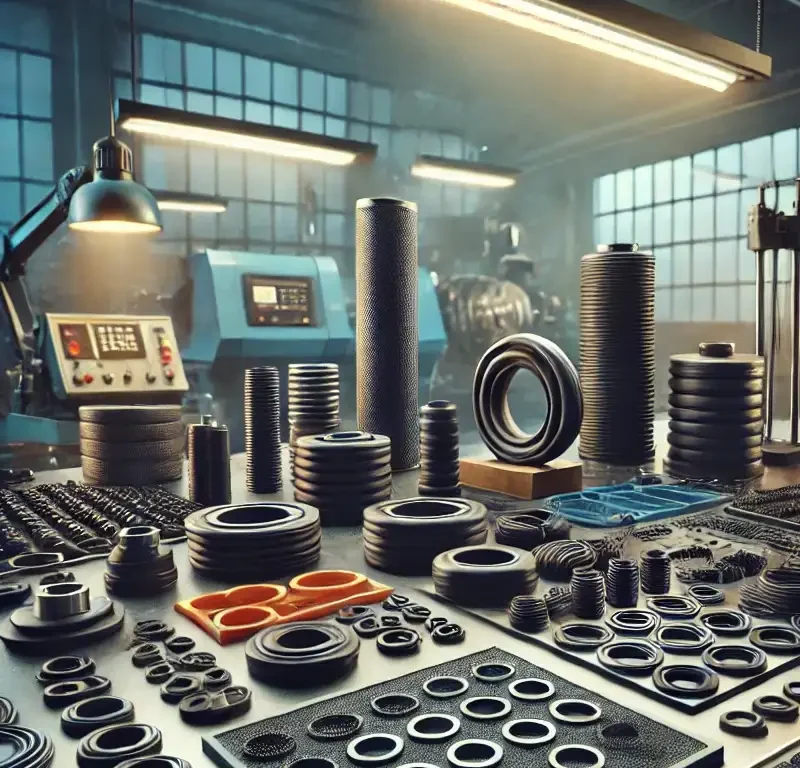

Industrial Rubber Products: Custom Solutions for Unique Industry Needs

March 5, 2025Introduction

Rubber products play a critical role in industrial applications, providing solutions that enhance efficiency, safety, and durability. Rubber product manufacturers have embraced technological advancements to produce customized rubber components that meet the high-performance demands of various industries. From seals and gaskets to vibration-dampening parts, these products are essential in industries such as automotive, aerospace, construction, and manufacturing.

1. Customized Solutions for Specific Industry Needs

Rubber manufacturers excel in creating custom rubber components tailored to the needs of different industries. Whether it’s a specific rubber seal for a pipeline, a custom gasket for machinery, or a durable rubber pad for industrial vehicles, manufacturers work closely with businesses to provide specialized products. Customization allows industries to improve efficiency, reduce equipment wear, and ensure safety in harsh environments.

2. Durability and High-Performance Rubber Components

Industrial applications demand rubber products that can withstand extreme conditions such as high temperatures, heavy loads, and exposure to chemicals or abrasion. Leading rubber manufacturers produce high-performance rubber components that maintain their integrity under tough conditions. This includes items like heavy-duty O-rings, industrial seals, and rubber parts that ensure machines operate smoothly with minimal downtime.

3. Vibration and Noise Reduction

Many industrial operations involve machinery that generates significant noise and vibration. To address this issue, rubber product manufacturers design anti-vibration mounts, buffers, and isolators that reduce noise pollution and minimize mechanical wear and tear. This improves the working environment and enhances the longevity of industrial equipment.

4. Eco-Friendly Manufacturing Processes

As sustainability becomes a growing priority, rubber manufacturers are implementing eco-friendly production methods. Many now utilize recycled materials, reduce waste, and adopt energy-efficient processes. By manufacturing eco-friendly rubber components, companies align with global efforts to reduce environmental impact while still producing durable and reliable products.

5. Chemical and Heat Resistance

Industries like oil and gas, chemical processing, and manufacturing require rubber components that can endure chemical exposure and high temperatures. Rubber manufacturers have developed specialized formulations, such as EPDM (Ethylene Propylene Diene Monomer) and Viton, to create rubber parts that are resistant to extreme temperatures and corrosive chemicals. This ensures that equipment and infrastructure remain protected in even the most demanding industrial environments.

6. Technological Advancements and Innovation

Rubber product manufacturers are continually evolving by adopting new technologies like computer-aided design (CAD) and automation in production. These advancements help create precision-engineered rubber components that meet strict specifications. Innovations such as 3D printing are also allowing for rapid prototyping, ensuring manufacturers can quickly develop and test rubber products for industrial applications.

Applications of Rubber Products in Industrial Settings

- Automotive Industry

In the automotive sector, rubber products like gaskets, seals, and hoses are critical for vehicle performance. Rubber components ensure that engines, brakes, and other systems operate efficiently. - Aerospace Industry

Rubber components in aerospace applications must be lightweight yet durable enough to withstand extreme altitudes and temperatures. Manufacturers produce seals, O-rings, and isolators that meet these stringent demands. - Construction and Heavy Equipment

Rubber tracks, pads, and vibration isolators are essential in construction equipment, reducing mechanical wear and providing a smoother operation for heavy-duty machinery. - Oil and Gas

In the oil and gas industry, rubber seals and gaskets are required to prevent leaks in pipelines, valves, and equipment, ensuring safety and efficiency.

FAQs

Q1: How are rubber products customized for industrial use?

Manufacturers work closely with industries to design and produce rubber components that meet specific performance and environmental requirements.

Q2: What makes rubber ideal for industrial applications?

Rubber is durable, flexible, and resistant to chemicals, heat, and abrasion, making it suitable for the tough conditions of industrial environments.

Q3: Are rubber components environmentally friendly?

Many manufacturers use recycled rubber materials and adopt eco-friendly production processes to reduce their environmental impact.

Q4: Can rubber products reduce noise and vibration in industrial settings?

Yes, rubber isolators and vibration mounts are commonly used to reduce noise and vibration, protecting both equipment and workers.

Q5: What industries benefit the most from rubber products?

Industries such as automotive, aerospace, construction, and oil and gas rely heavily on durable rubber components for efficiency and safety.