Hose Clamp

April 8, 2020

Food & Pharmaceutical Grade Hoses

April 26, 2020high-pressure-Hydraulic-hose

used for transporting liquid “fluid one component to other and meanwhile it provides an inherent versatility to designers.” (Ali Enterprises Pakistan) going to explain about Hydraulic Hose.

A hydraulic hose is in particular designed to carry hydraulic fluid to or amongst hydraulic components, valves, actuators, and tools. It is commonly flexible, regularly reinforced, and commonly constructed with numerous layers of reinforcement considering hydraulic systems often operate at excessive or very high pressures. Hydraulic hose is used in quite a few industrial hydraulic systems. Dimensions, performance specs, construction options, and capabilities are crucial parameters to take into account when searching for hydraulic hose.

Important dimensions for the choice of hydraulic hose encompass the inner diameter, outdoor diameter, and minimum bend radius. Hydraulic hose sizes are denoted through the inside and outside diameter of the hose. The inside diameter refers to the internal of the hose or liner. The outside diameter is mostly a nominal specification for hoses of corrugated or pleated construction. The minimum bend radius is based totally on a mixture of perfect hose cross-section deformation and mechanical bending limit of any reinforcement.

high-pressure-Hydraulic-hose

_

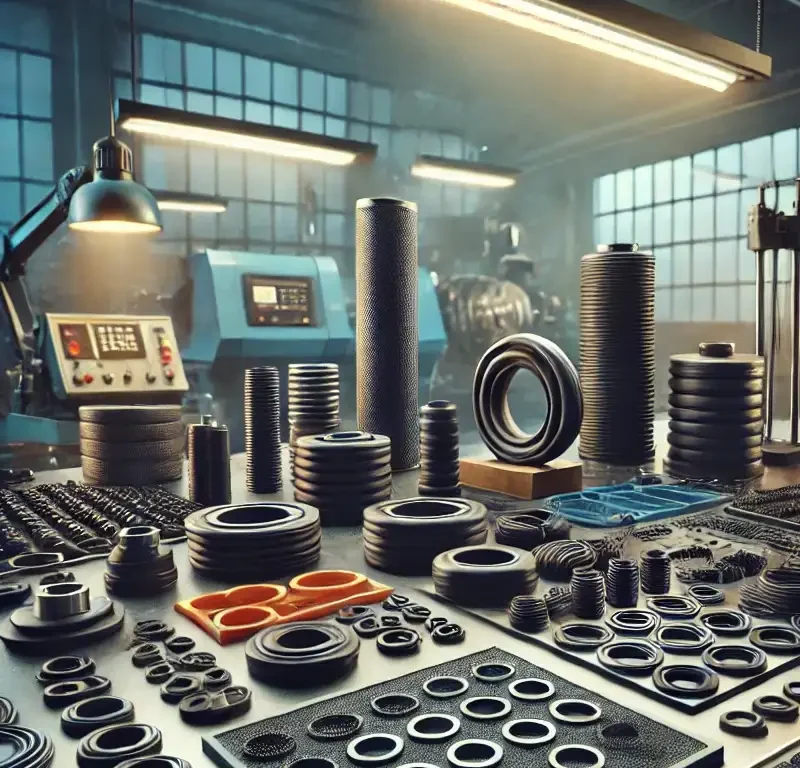

Construction options for hydraulic hose include reinforced, coiled, corrugated, or convoluted. The reinforced hose is built with some elements of reinforcement—styles include fabric braid, twine braid, wire helix, and other designs in many ply or layer configurations. The coiled hose is coiled for flexibility and elasticity. This function regularly makes it expandable and clean to store. Corrugated hose carries corrugations, pleats,

Hydraulic hoses for high working pressure

or spiral convolutions to boom flexibility and potential for compression and elongation. Multi-detail hydraulic hoses are constructed of more than one hose fashioned or adhered together in a flat, ribbon, or bundled configuration. Additional functions to remember encompass critical quit connections, anti-static, lay flat, crush-proof, flame-resistant, and explosion-proof.

In addition, fabric considerations include the form of fluid being conveyed and its concentration as well as substances that can assault the hose cover. Hose choice must make certain compatibility if it’s miles to bring unique oils or chemicals. The identical holds for hose uncovered to harsh environments. Substances together with UV light, ozone, saltwater, chemicals, and pollution can purpose degradation and untimely failure. For in-intensity fluid compatibility data, consult the manufacturer.

While hydraulic hose is generally constructed of more than one substance, the most usually use primary materials encompass elastomers, fluoropolymers and silicone, thermoplastics, metal, and composite or laminated structures. Elastomeric or rubber hydraulic hose are often selected for their flexibility. Fluoropolymer hose provide properly flex life, advanced chemical and corrosion resistance, and may deal with high temperatures.

high-pressure-Hydraulic-hose

The thermoplastic Hydraulic hose provides tight minimum bed radii and extraordinary kink resistance. Metal hoses can cope with high-temperature flow substances and regularly can take care of very high pressures. They can be both stiff or flexible.

Flexible hoses are simpler to the course and install, compared with inflexible tubing and pipe. They lessen vibration and noise, dampen strain surges, and permit motion between parts. In addition, customer increasing needs for higher productivity, efficiency, and environmental compatibility are forcing hose manufacturers to enhance product integrity—hoses now withstand higher pressures, extreme heat and cold, and accommodate a number fluids including today’s “green” variants.

Most hoses are synthetic to SAE J517 or European Norm (EN) Standards, the latter based on in advance DIN German requirements. These standards predominate inside the Americas, Europe, and Australia. Both are also used at some point of Asia, even though that marketplace is slowly gravitating towards EN specs primarily due to the fact EN-rated hose has a better strain rating in comparison with similar-sized SAE hose. This gives greater protection elements should an utility not need the very best working pressure.

Note: Contact us for buying any kind of Hydraulic Hose because we are manufacturer supplier in Lahore Pakistan we have a long range of industrial rubber parts and products you can visit our website “https://alienterprisepk.com”

<hr>

For creative website and Blog click here