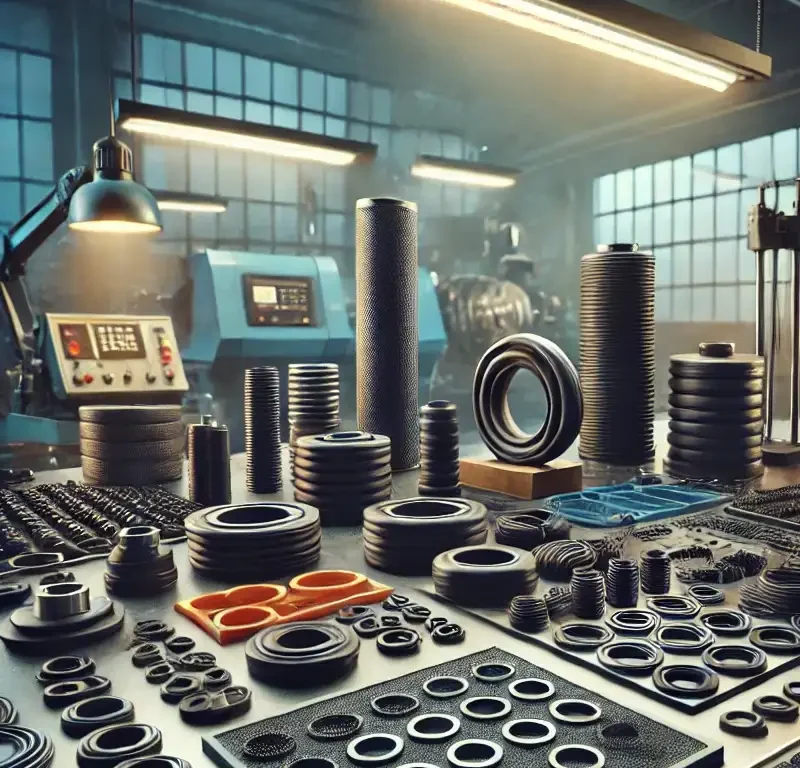

How Industrial Rubber Parts Drive Innovation in Manufacturing

April 5, 2025

Ali Enterprises’ Rubber Innovations: The Future of Industrial Products

April 25, 2025Introduction Concrete pump pistons are critical components in the construction industry, playing a vital role in the efficient and effective delivery of concrete. These pistons ensure the smooth operation of concrete pumps, enabling the precise placement of concrete in various construction projects.

What Are Concrete Pump Pistons?

1. Functionality Concrete pump pistons are designed to push concrete through the pump’s cylinder, allowing it to be transported to the desired location. The piston’s movement creates the pressure needed to move the concrete, ensuring consistent flow and reducing the risk of blockages.

2. Material Composition These pistons are typically made from high-grade materials like polyurethane or rubber, chosen for their durability and resistance to abrasion. The material ensures that the piston can withstand the harsh conditions of pumping abrasive concrete mixtures.

Applications of Concrete Pump Pistons

1. High-Rise Buildings Concrete pump pistons are essential in delivering concrete to high-rise construction sites, where traditional methods would be inefficient or impossible.

2. Infrastructure Projects They are widely used in infrastructure projects such as bridges, tunnels, and highways, where large volumes of concrete need to be transported over long distances or to elevated positions.

Benefits of Using Quality Concrete Pump Pistons

1. Enhanced Efficiency High-quality pistons ensure a smooth and consistent flow of concrete, minimizing downtime and enhancing overall project efficiency.

2. Longevity and Durability Investing in durable pistons reduces the frequency of replacements and maintenance, saving time and money in the long run.

3. Precision in Concrete Placement Concrete pump pistons enable precise placement of concrete, crucial for meeting design specifications and ensuring the structural integrity of construction projects.

Conclusion

Concrete pump pistons are indispensable in modern construction, offering the precision, durability, and efficiency needed to complete complex projects on time and within budget. By choosing high-quality pistons, contractors can ensure the smooth operation of their concrete pumps and the successful completion of their projects.

FAQs

1. What are concrete pump pistons used for? They are used to move concrete through the pump’s cylinder, enabling the delivery of concrete to specific locations on a construction site.

2. What materials are concrete pump pistons made from? Typically made from durable materials like polyurethane or rubber to withstand the abrasive nature of concrete.

3. How do concrete pump pistons improve efficiency? They ensure a consistent flow of concrete, reducing blockages and minimizing downtime during construction projects.

4. Can concrete pump pistons be customized? Yes, pistons can be customized to fit specific pump models and meet particular project requirements.

5. Where can I find reliable concrete pump pistons? High-quality concrete pump pistons can be sourced from reputable suppliers like Ali Enterprises, known for their durable and efficient construction components.