You Won’t Believe the Range of Rubber Products at Ali Enterprises!

March 25, 2025

Understanding Concrete Pump Pistons: Essential Components for Efficient Construction

April 15, 2025Introduction Innovation in manufacturing is often driven by the development and application of advanced materials, and industrial rubber parts are no exception. These components are not only essential for the smooth operation of machinery but also play a crucial role in advancing sustainable and efficient manufacturing practices.

The Role of Industrial Rubber Parts in Innovation

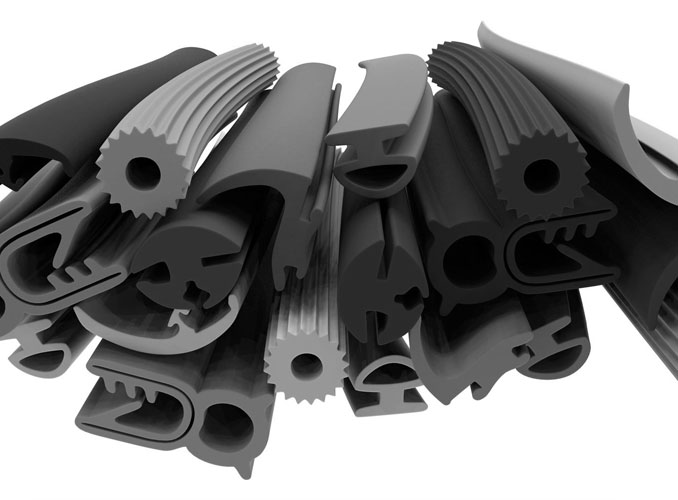

1. Enhancing Machinery Efficiency Industrial rubber parts, such as seals, gaskets, and anti-vibration mounts, are designed to improve machinery efficiency by reducing wear and tear, preventing leaks, and minimizing vibrations. These improvements lead to longer machinery life and less downtime, which is critical for innovative manufacturing processes.

2. Supporting Sustainable Practices Sustainability is a key focus in modern manufacturing. Advanced rubber materials, such as those with enhanced durability and recyclability, contribute to greener manufacturing processes by reducing waste and the need for frequent part replacements. This shift towards sustainable materials is fostering innovation in how products are designed and produced.

3. Customization and Precision The ability to customize industrial rubber parts for specific applications allows manufacturers to innovate in product design and function. Custom rubber components can be tailored to meet the exact needs of a manufacturing process, leading to more efficient operations and higher-quality products.

Case Study: Revolutionizing Automotive Manufacturing

A leading automotive manufacturer integrated custom-designed rubber components into their assembly line, resulting in a 20% increase in production efficiency and a significant reduction in material waste. This example illustrates how tailored industrial rubber parts can drive innovation in manufacturing processes.

Conclusion

Industrial rubber parts are more than just components—they are enablers of innovation in manufacturing. By enhancing machinery efficiency, supporting sustainable practices, and allowing for customization, these parts are at the forefront of modern manufacturing advancements.

FAQs

1. How do industrial rubber parts contribute to manufacturing efficiency? They reduce machinery wear and tear, prevent leaks, and minimize vibrations, leading to longer machine life and less downtime.

2. What role do rubber parts play in sustainable manufacturing? Rubber parts made from durable, recyclable materials reduce waste and the need for frequent replacements, supporting greener manufacturing practices.

3. Can industrial rubber parts be customized? Yes, customization allows manufacturers to create parts that meet specific needs, enhancing the efficiency and precision of manufacturing processes.

4. How do rubber parts foster innovation in product design? Custom rubber components enable innovative designs by providing precise solutions that meet the unique requirements of different manufacturing processes.

5. What industries benefit the most from innovative rubber parts? Industries such as automotive, aerospace, and electronics benefit significantly from the use of advanced, customized rubber parts in their manufacturing processes.