Leading the Way in Rubber Product Manufacturing for Industrial Applications

March 1, 2025

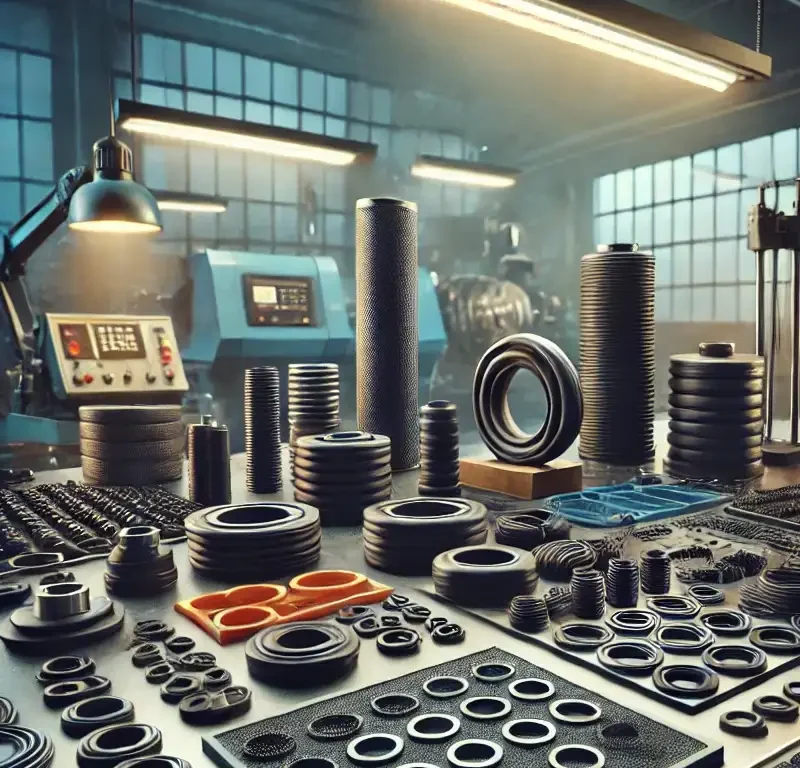

The Importance of Custom Gaskets in Industrial Applications

March 15, 2025Introduction In the diverse landscape of industrial operations, one size rarely fits all. Customized industrial rubber products offer the flexibility and precision required to meet specific industry needs, enhancing both efficiency and performance.

The Advantages of Custom Industrial Rubber Products

1. Tailored Fit for Specific Applications Customized rubber products are designed to meet the exact specifications of your machinery or process. This ensures optimal performance, reduces wear and tear, and extends the lifespan of both the rubber components and the machinery.

2. Enhanced Performance and Efficiency When rubber products are tailored to your specific needs, they function more efficiently, providing better sealing, vibration damping, or protective capabilities. This leads to smoother operations and reduces the risk of unexpected breakdowns.

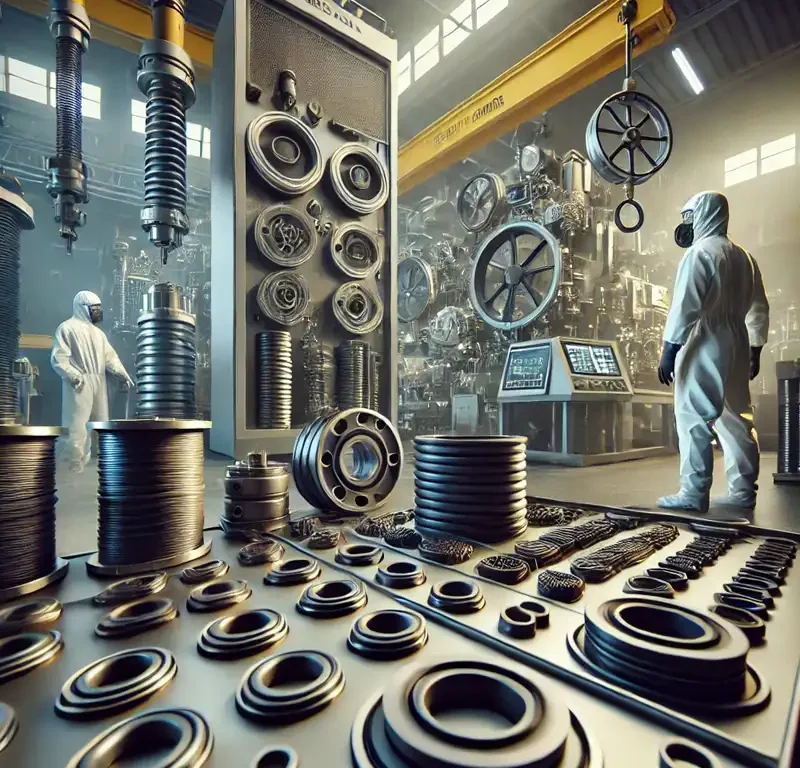

3. Industry-Specific Solutions Different industries have unique demands. For example, the automotive industry may require rubber components that can withstand high temperatures and pressures, while the food processing industry might need products that comply with strict hygiene standards. Customization allows you to meet these specific requirements.

Key Customization Options

1. Material Selection The choice of rubber material is crucial for ensuring that the product can withstand the environmental conditions it will face. Options include:

- EPDM: Resistant to heat, ozone, and weathering.

- Nitrile (NBR): Excellent for oil and fuel resistance.

- Silicone: Ideal for extreme temperature conditions.

2. Design and Dimensions Custom rubber products can be molded or extruded into precise shapes and sizes, ensuring a perfect fit for your equipment or application.

3. Additional Features Customization also allows for the integration of additional features such as color coding, branding, or specific surface textures that enhance the product’s functionality.

Case Study: Meeting Unique Needs in the Automotive Industry

An automotive manufacturer needed a rubber component that could withstand high engine temperatures while providing a reliable seal. By opting for a customized solution, they were able to develop a part that not only met these requirements but also improved overall engine performance, reducing the need for frequent replacements.

Conclusion

Custom industrial rubber products offer unparalleled advantages by meeting the specific needs of various industries. By working closely with a reliable supplier, you can develop solutions that enhance your operations, increase efficiency, and reduce costs.

FAQs

1. Why should I opt for custom rubber products? Custom rubber products are tailored to meet specific requirements, ensuring better performance and longevity compared to standard options.

2. What industries benefit from custom rubber products? Industries such as automotive, food processing, and manufacturing benefit greatly from customized rubber solutions that meet their unique needs.

3. How can custom rubber products improve efficiency? By fitting perfectly and being designed for specific applications, custom rubber products reduce wear and tear, leading to smoother operations and less downtime.

4. What are the customization options available? Customization options include material selection, design and dimensions, and additional features such as color coding or specific textures.

5. How do I get started with ordering custom rubber products? Start by consulting with a reputable supplier who can guide you through the process of designing and manufacturing rubber products tailored to your needs.